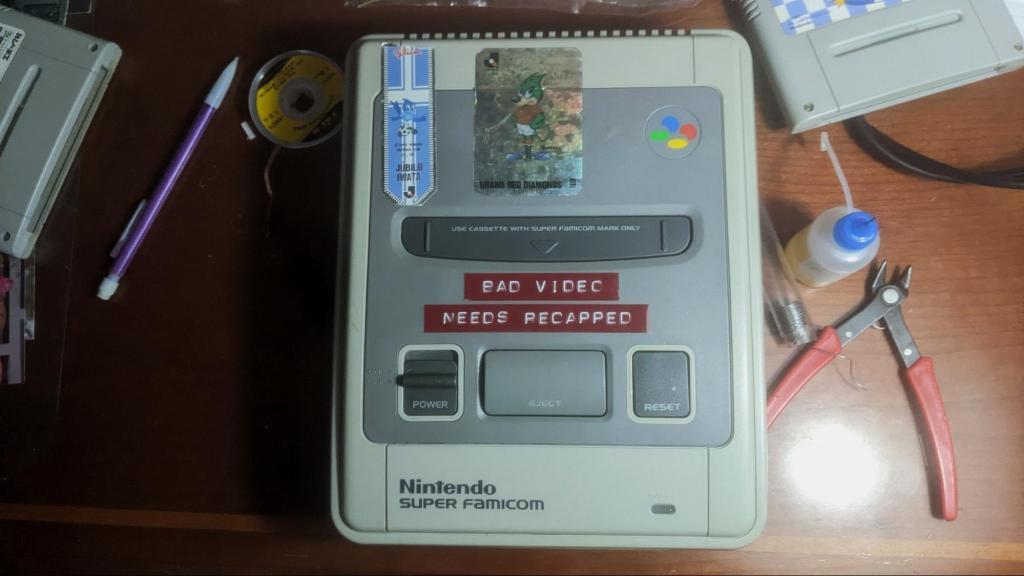

My dad has always worked in manual labor. He would often say, ‘Anyone can do my job; the hard part is making money doing it.’ After dealing with this 50 lb. box of broken ’90s technology, I completely understand what he meant. My plan was to fix the lot and resell the items, but I didn’t anticipate all 22 having issues, ranging from dirty reset switches to faulty CPUs. I did manage to fix some and sell a few, but did I actually make any money?

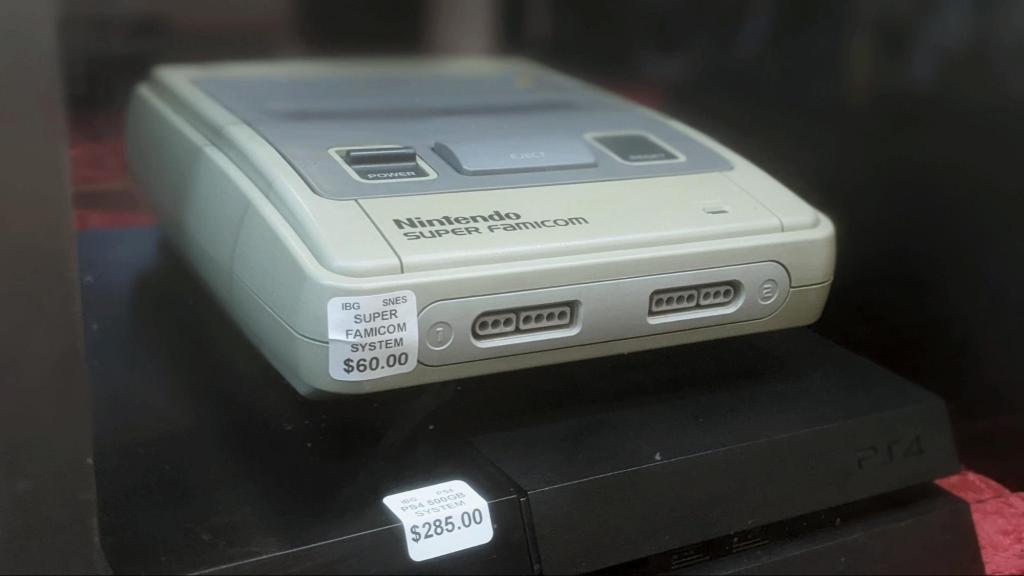

No, I didn’t make any money. The ones I did manage to fix, I sold to a local retro game store. It felt good to see my work on display, ready to be sold, reused, and enjoyed. But good feelings don’t pay the bills! Anyway, most of the fixes were either boring or not worth doing. I plan to swap a PPU and GPU in the future, but today’s blog isn’t about that.

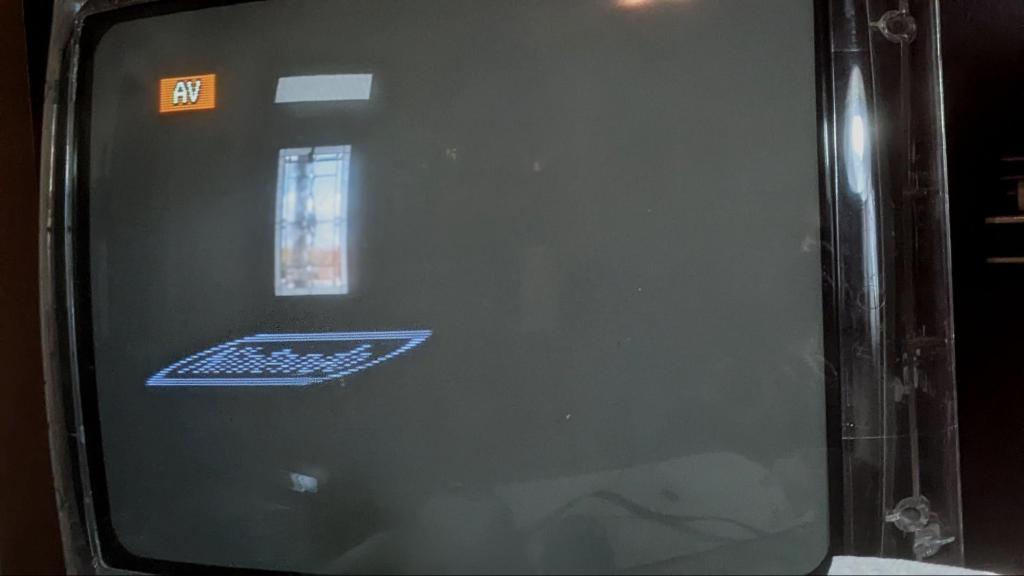

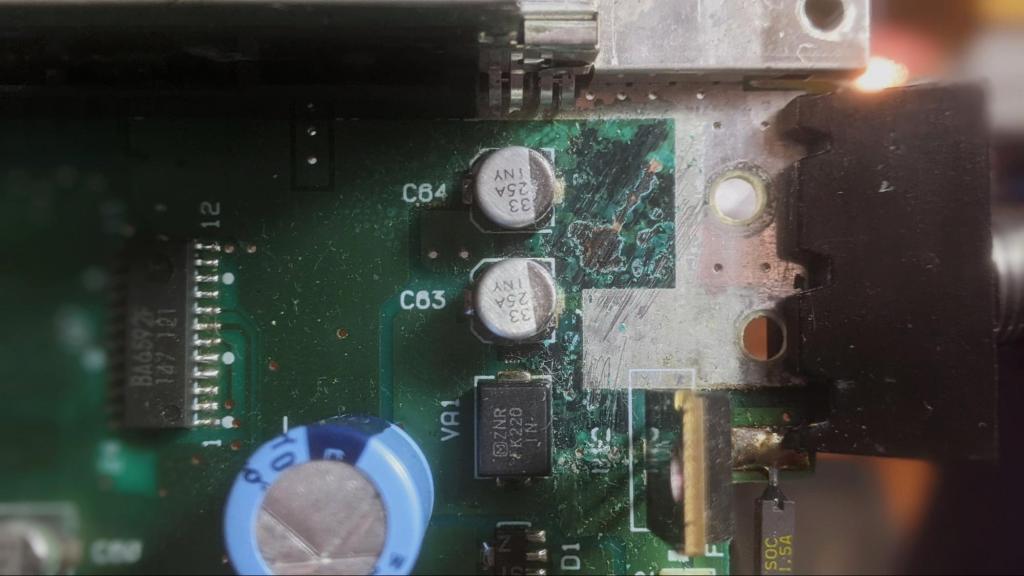

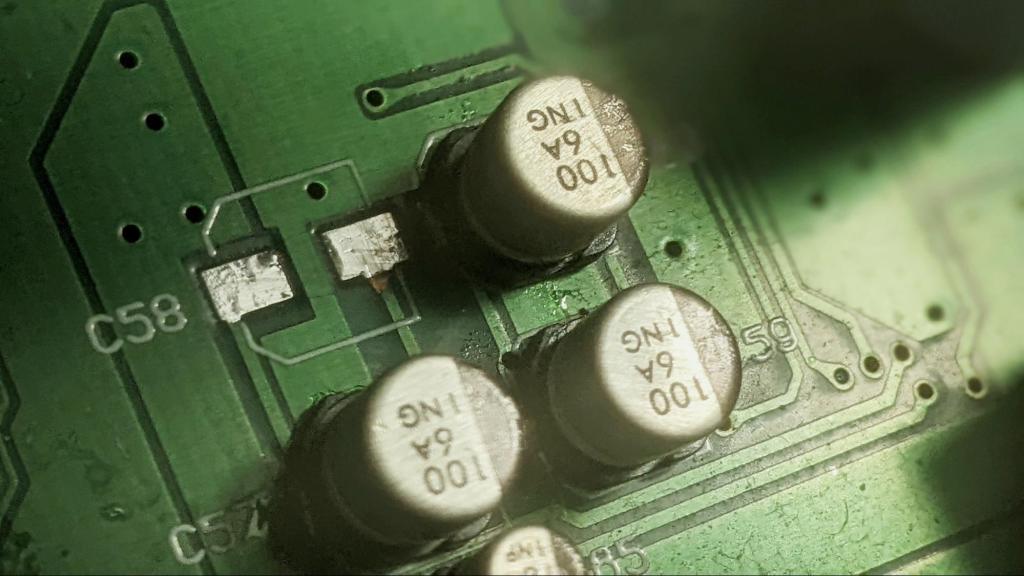

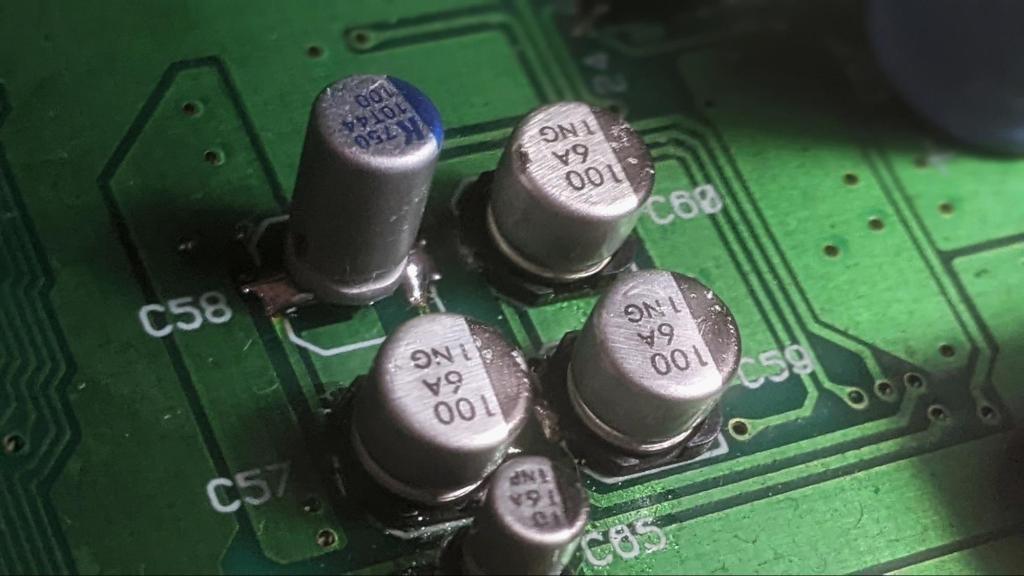

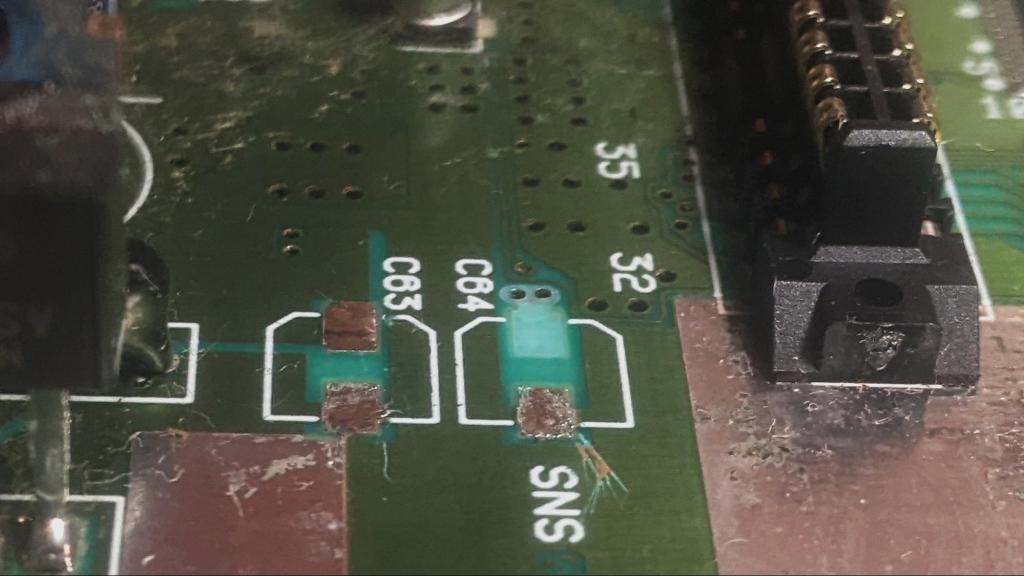

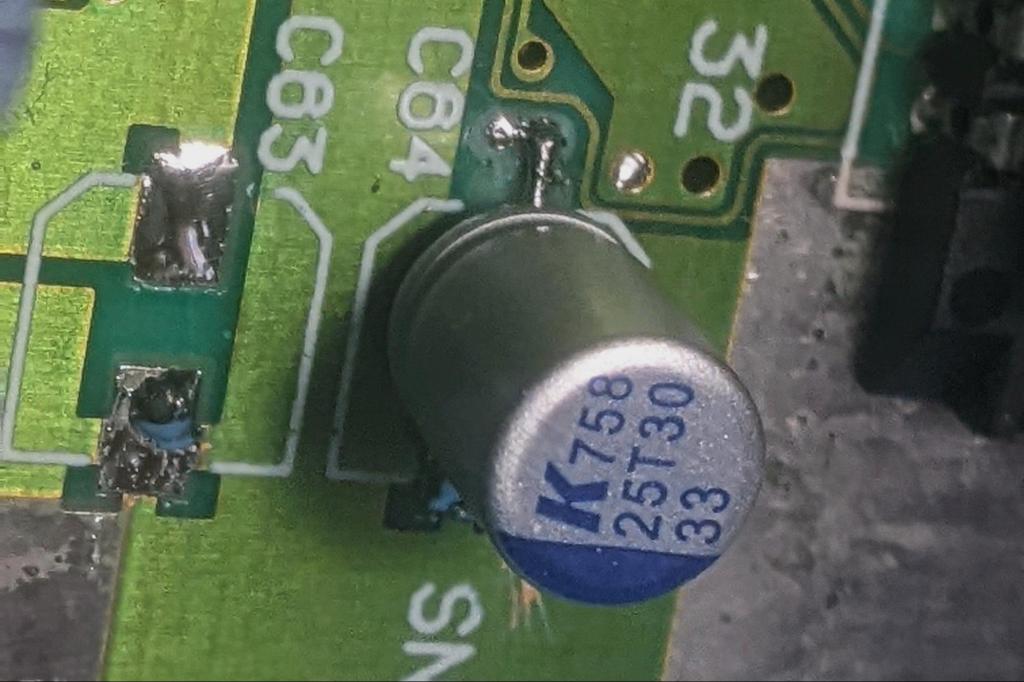

Wavy and distorted images can happen when using a cheap power supply, but I know it’s not my power supply. The issue is with the two capacitors next to the voltage regulator. The suspect capacitors are C64 and C63.

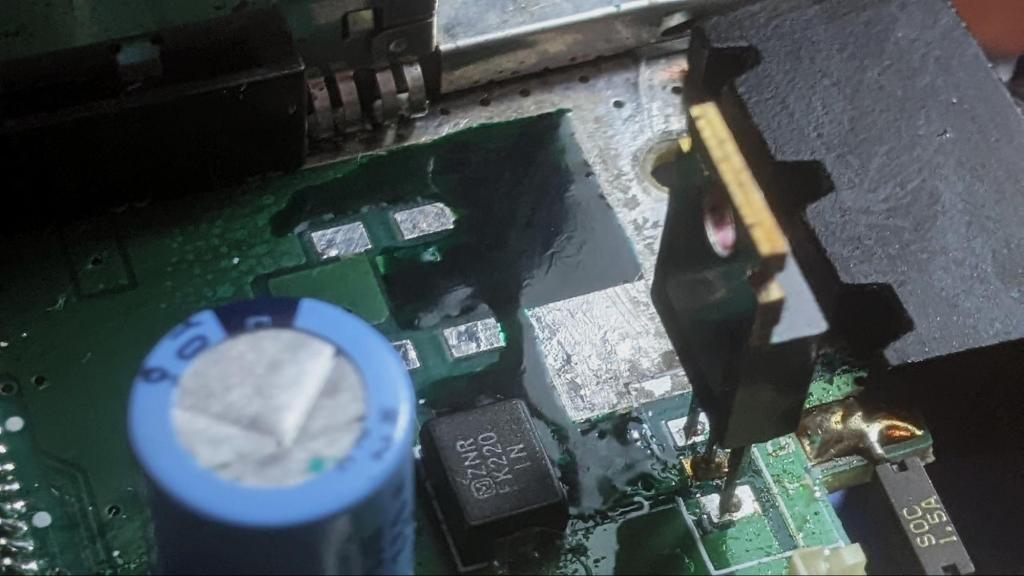

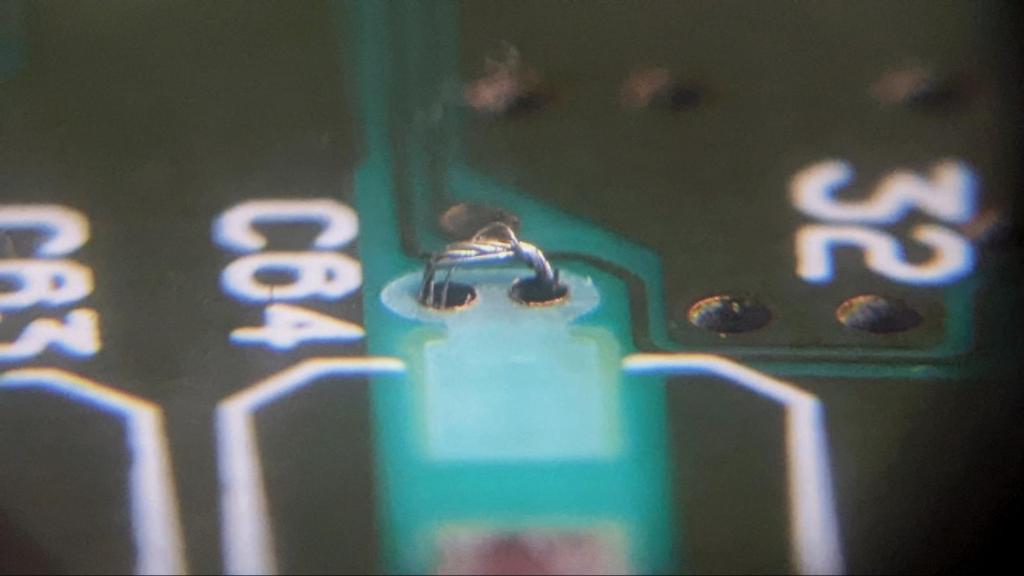

Yeah, that’s some corrosion. I’ll need to scrape it all off, but doing so will expose the copper ground plane and surrounding traces. This exposure could lead to future corrosion. So, I’ll need to spend some time here applying solder mask.

Here’s all the forensic evidence from our suspects—corrosion from leaking capacitors. It’s pretty bad. No wonder the image was so wavy.

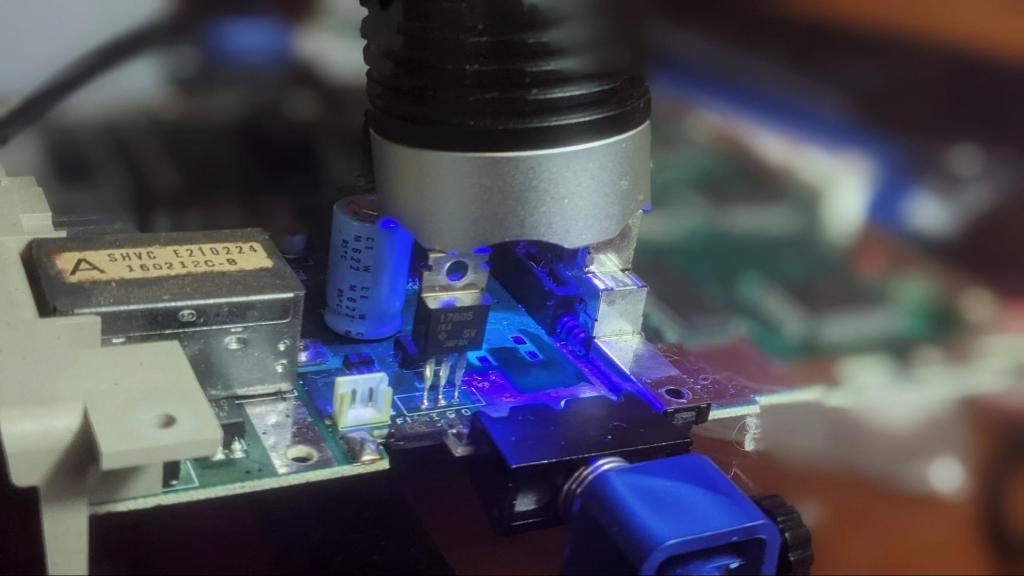

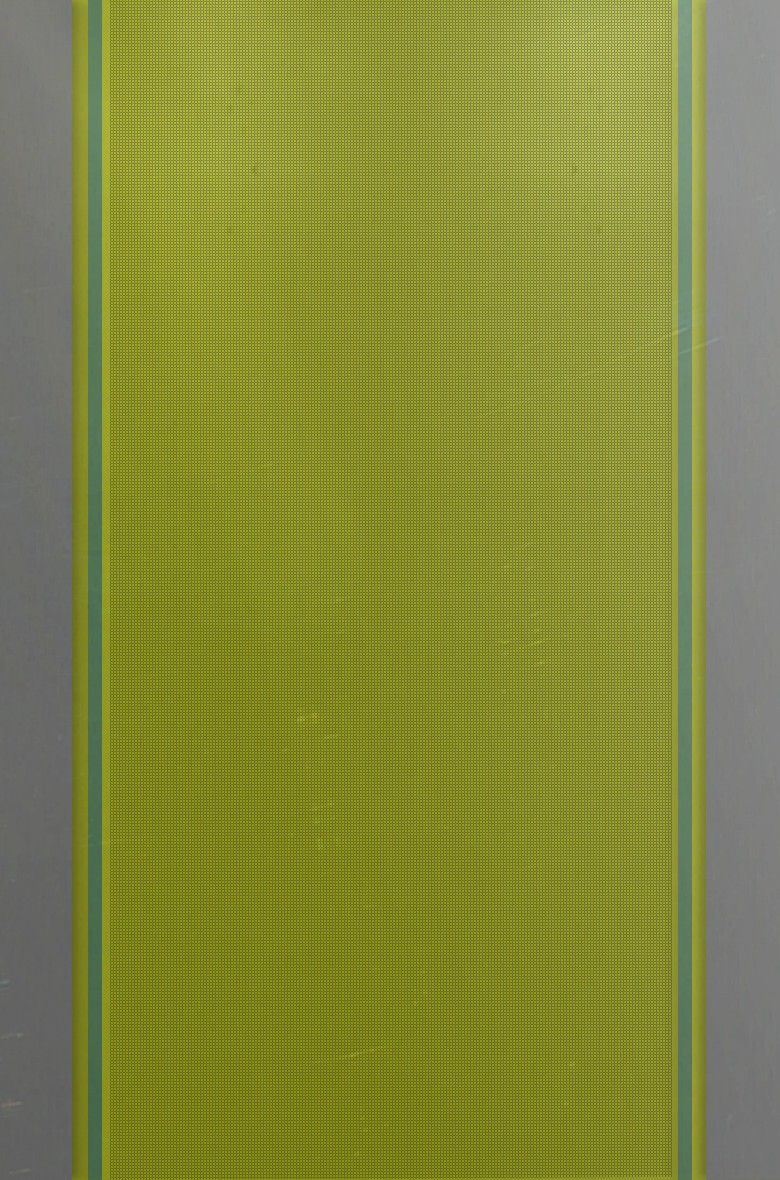

This is the green tube of goo I’ll be using. M e c h a n i c

I put a small drop on the board, then smear it around with my tweezers. A little goes a long way.

It takes about 5-10 minutes for the UV light to cure the solder mask, which was the perfect amount of time to reflect on the costly mistake sitting in the 50 lb. box next to me. I bought the 22 Super Famicoms on Yahoo Auction for an okay deal. The cost of shipping was high, but I bought some other cool things for a friend, so we shared the shipping cost. I felt nervous about the deal, but I had confidence. I figured I could get at least 20 into a sellable state. Big mistake. I should have been more realistic. If I had expected only 50 percent to be salvageable, I would have found a cheaper deal.

Just like new! (not really) Now to continue and replace C64 and C63.

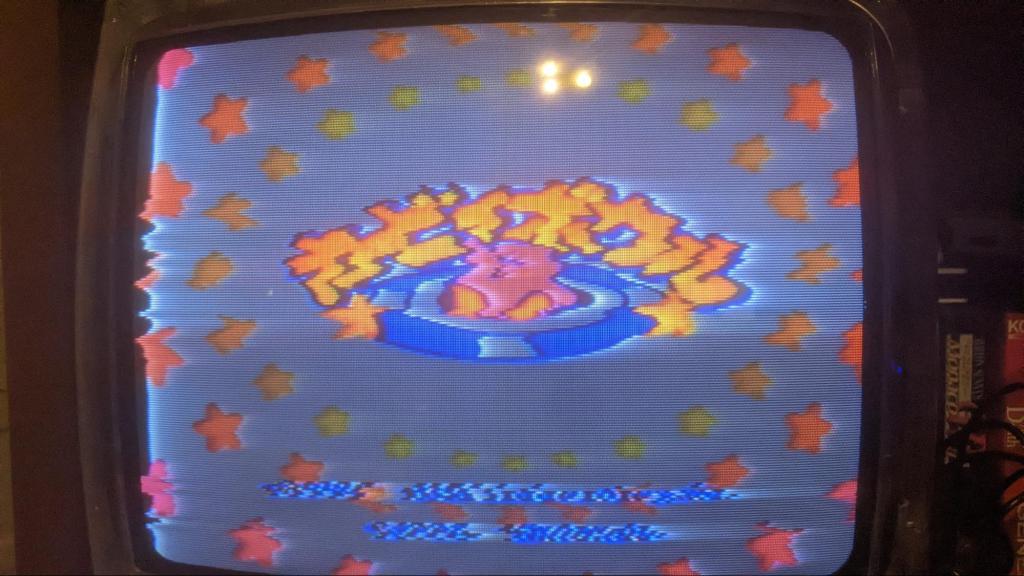

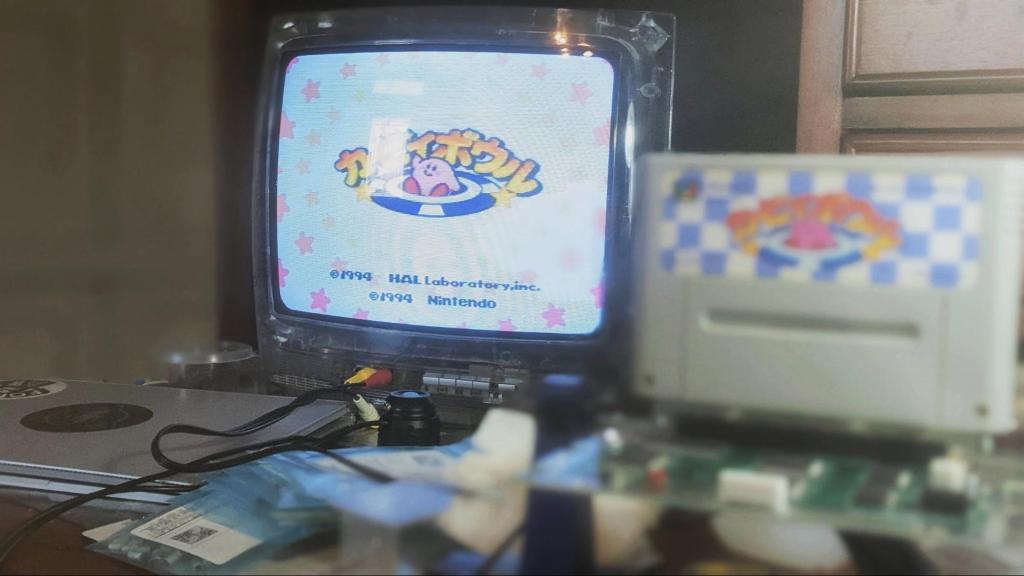

Let’s test and see if that fixed the issue.

Well, that ain’t right. The distortion is gone, but the low contrast and waviness means the Super Famicom has a bad filter capacitors. Suspect C58!

cursed image

C’ya, C58. I traced continuity from the video composite plug, through the AV cable, to this capacitor.

That should do the trick!

Finally! Now to blog about the remaining 21 consoles—psych! Of course, I’m not going to show all 22, but I did have some misfortune during a few cap removals. I’ll show the most annoying ones.

Tale as old as time, song as old as rhyme. Wavy, distorted image, suspect C63 and C64, but whoops! I ripped the solder pad off.

I threaded a wire through one of the vias that connected to the solder pad.

With the wire I “stitched” the two vias together

It’s not much of an anchor, but it’s the best for the situation.

In summary, 9 of the units had simple repairs, like broken traces, faulty power switches, or reset switches. 6 of the units needed capacitors, 6 units had faulty CPUs or PPUs, and 1 unit couldn’t be diagnosed.

After managing to fix 15 of the 22 units, I was able to sell some of them to a local retro game shop. It felt good seeing my hard work out there for others to enjoy, but with the remaining consoles still in need of repairs, I’ve learned that not every deal is as good as it seems. The ones that are fixed are now out for sale, hopefully finding new homes where they can be appreciated. It was a challenging project, but it taught me a lot about repairs, expectations, and the reality of buying in bulk.

Even though I didn’t make any money, seeing this is still pretty cool.

Until next time, later nerds!

Leave a comment